With high atmospheric CO2 concentrations now recognised as the principal cause of climate change, the EU has set an ambitious goal of achieving zero CO2 emissions by 2050. To reach this target, hard-to-abate (HTA) sectors such as construction, cement, steel, chemicals and ceramics – all of which are key drivers of the Italian economy – are called on to reduce their CO2 emissions by 55% by 2030 compared to 1990 levels.

In light of this, the ceramic tile industry has an important role to play in promoting the ecological transition and sustainable development. In 2021, Italy ranked as the world’s sixth largest producer of ceramic tiles with a production volume of approximately 430 million square metres. The Emilia-Romagna region, home to a ceramic tile manufacturing cluster spanning the provinces of Modena and Reggio Emilia, accounts for more than 90% of national production. Moreover, global ceramic tile production is projected to grow at an average annual rate of 5% from 2021 to 2025.

It is therefore imperative for the ceramic tile sector to intensify its efforts to reduce CO2 emissions. Sustainability and the circular economy are important milestones for promoting policies aimed at reducing raw materials consumption, minimising waste production and disposal costs, and encouraging recycling and reuse technologies.

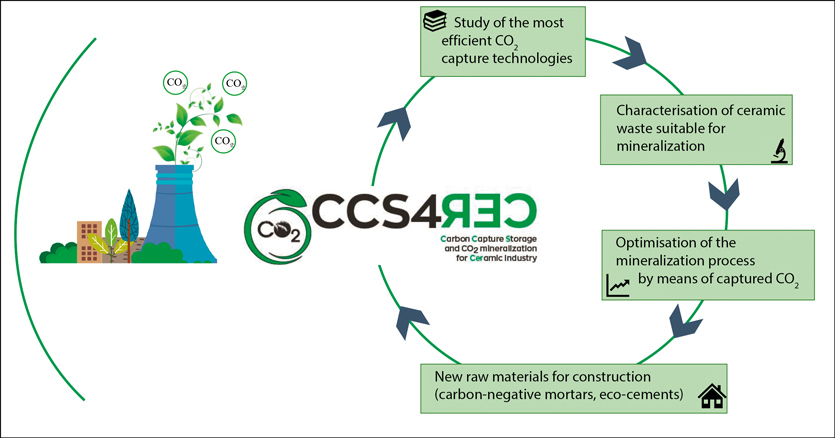

This led to the launch of a project entitled CCS4CER: Carbon Capture storage and CO2 mineralization for Ceramic Industry, financed with European funds allocated by the Emilia-Romagna Region, PR-FESR 2021/2027, Axis 1 Research, Innovation and Competitiveness, Action 1.1.2 The aim of the project is to identify the most effective method for capturing CO2 emissions from ceramic manufacturing facilities and to explore new ways of recycling currently unused waste (e.g. spent lime) through mineralization processes.

The CCS4CER project, coordinated by Centro Ceramico, involves the participation of the following laboratories from the Emilia-Romagna Region’s High Technology Network: CIRI-FRAME at the University of Bologna, LEAP at Milan Polytechnic, and Romagna Tech. Leading companies in the ceramic cluster, including Ascot Gruppo Ceramiche, Panariagroup Industrie Ceramiche S.P.A. and SACMI Cooperativa Meccanici Imola S.C., are also participating but without funding.

Along with the involvement of sector companies, the real strength of the partnership lies in the multidisciplinary expertise of the players involved. Centro Ceramico provides its knowledge of the process and characterisation of raw materials, finished products and residues, as well as its experience in technology transfer. CIRI FRAME focuses on optimising mineralization processes at the laboratory scale, while LEAP contributes its extensive experience in energy and the environment for the modelling of capture systems. Romagna Tech will be responsible for disseminating the project’s findings.

Following the signing of the agreement on 15 February 2024, a series of preliminary meetings were held between the partners before initiating the project’s activities, which are organised into six work packages (WPs) over a 30-month period.

The first phase consists of an analysis of the ceramic tile industry’s context, including identification and characterisation of the most suitable ceramic waste for the mineralization process supplied by corporate partners and other manufacturers. Special attention will be focused on spent lime from flue gas abatement. Although almost all the fired and unfired waste produced in the ceramic tile production process is recycled, spent lime is currently sent to landfill as hazardous waste. It is estimated that approximately 365,000 tonnes of spent lime from Italian tile production was disposed of in 2020.

However, this spent lime can be converted into CaCO3 by means of a mineralization reaction with CO2, which in the future will preferably be captured and recycled directly from the same production plant. This process will be studied and optimised by evaluating the best operating conditions for the gas and liquid phases. The resulting materials such as CaCO3, CaF2 and CaSO4 will then be tested for use as new raw materials for the construction industry (carbon-negative mortars and/or eco-cements). Additionally, the project will evaluate the most suitable decarbonisation technologies currently on the market in terms of energy and environmental costs and suitability for the ceramic tile production process.

The project’s goals include: (I) reducing CO2 emissions through capture, (II) transforming waste (including hazardous waste) into predominantly carbonate-based products via CO2 mineralization, (III) utilising the resulting products as secondary raw materials in construction to ensure a low environmental impact.

The project’s results are therefore expected to align with the European mandate for a climate neutrality roadmap and to boost the long-term competitiveness of the Italian ceramic tile industry, which for many years has been recognised as a global model for technological innovation and environmental sustainability.

Authors: Valentina Scognamiglio(1), Maria Chiara Bignozzi(1), Stefania Albonetti(2), Maurizio Spinelli(3), Laura Saragoni(4)

1 Centro Ceramico, Sassuolo (MO), Italy

2 Dip. Chimica Industriale “Toso Montanari”, Bologna (BO), Italy

3 Politecnico di Milano, Energy Department, Milano (MI), Italy

4 Romagna Tech, Faenza (RA), Italy

Architects

Architects

Construction firms

Construction firms

Dealers

Dealers

Installers

Installers

Public

Public