A new type of ceramic surface has been developed with a reduced environmental footprint and identical technical and aesthetic characteristics to those of products manufactured using conventional methods. It is the result of the Wincer project, which allows ceramic tiles to be produced almost entirely from waste materials.

Wincer project

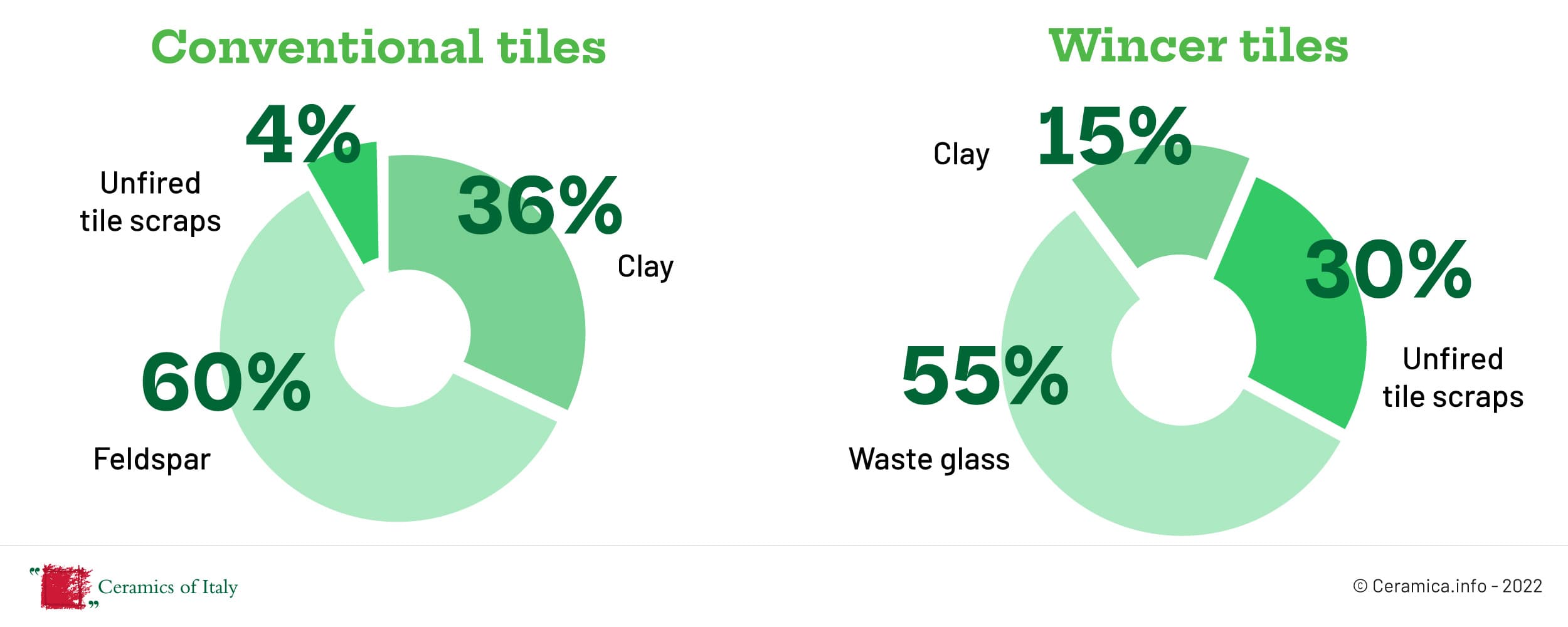

Italian ceramic tile producers have participated in numerous research initiatives focusing on sustainable products. One of these is the European WINCER project (http://www.wincer-project.eu/) coordinated by Centro Ceramico to produce tiles from materials recycled from municipal and industrial waste. The project was carried out in the period 2015-2018 and thanks to the collaboration of corporate partners led to the industrial-scale production of the first tiles containing 85% secondary raw materials.

Italian ceramic tiles. From earth, for the Earth

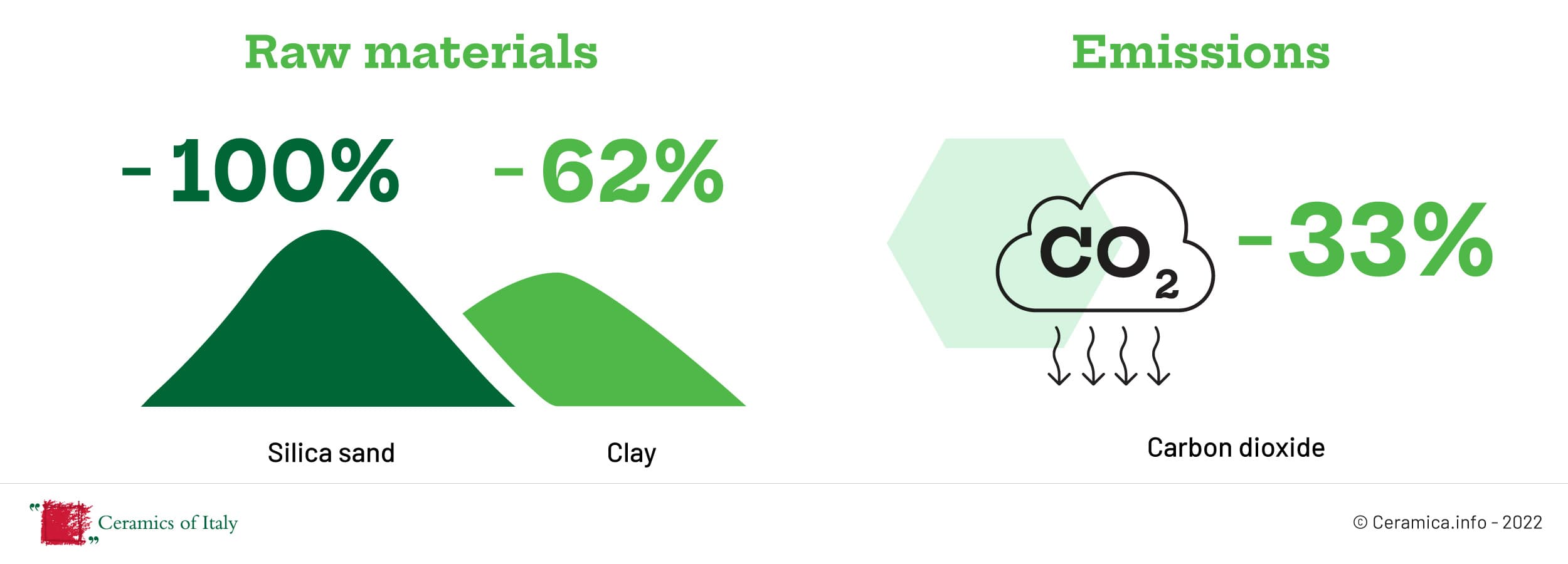

WINCER tiles ensure significant savings of natural resources by completely replacing feldspars and silica sands and partially replacing clays with glass and unfired tile scraps. This leads to an overall improvement in the ceramic industry’s environmental performance in terms of less use of natural raw materials, reduced energy consumption and lower CO2 emissions.

Origin of secondary raw materials

55% of Wincer tiles are made from glass originating from municipal waste collection, specifically the finest fraction (smaller than 100 microns) that cannot be reused for the production of glass packaging. Dust, sludge and unfired tile scraps account for 30% of the final product.

How a Wincer tile is produced

The Wincer tile production cycle is similar to that of the conventional process. The raw materials are ground with water in a continuous mill to form the slip. The liquid suspension is then sent to spray dryers, which produce a granular powder ready for pressing. After pressing, the tiles are dried and sent to the kilns. The firing phase reaches a maximum temperature of 1025°C instead of 1250°C as with a normal porcelain tile, with a duration of 39 minutes, as in the conventional process.

Certified performance

The temperature reached during firing is sufficient to ensure that Wincer tiles have a high impact resistance and less than 0.5% water absorption. This level of performance guarantees compliance with the UNI-Certiquality mark and with standard EN 14411 for the purposes of CE and UNI Keymark certification.

To evaluate the potential environmental impact of Wincer tiles, an LCA study was conducted in accordance with EN 15804 “Sustainability of construction works”, which confirmed the product’s sustainability footprint.

Architects

Architects

Construction firms

Construction firms

Installers

Installers

Public

Public