According to the CA4BM (Carbon Accounting for Building Materials) study, presented to a large and highly attentive audience at the latest edition of Cersaie with a focus in particular on ceramics, the best option for achieving a decarbonised built environment is to continue to decarbonise the manufacture of all construction materials across their whole life cycle. The study reflects the importance of achieving a carbon-neutral economy by 2050, a pivotal objective within the European Green Deal. To effectively mitigate the impacts of climate change, it is imperative to thoroughly assess the environmental impacts of building materials throughout their life cycles using comprehensive and reliable data. This evaluation serves as a basis for informed decision-making. For this reason, it is essential to promote the involvement and accountability of all stakeholders, including institutional bodies, in providing decarbonised energy carriers at a competitive cost.

The study, commissioned by a coalition of European and international federations representing the mineral building products sector (including Cerame-Unie, the European Ceramic Industry Association of which Confindustria Ceramica is a member) and conducted by LBP Sight and Royal Haskoning DHV, aims to advance scientific knowledge regarding methodologies for assessing the environmental impact of building materials. The ultimate goal is to promote a commitment to decarbonisation through standardised assessment methods. This scientific approach intends to assist policymakers in formulating appropriate European policies conducive to sustainable decarbonisation efforts within the building materials sector.

“Collectively, buildings in the EU are responsible for around 30% of greenhouse gas emissions,” said Dirk-Jan Simons, consultant and partner at LBP Sight. “Increased use of biobased products is perceived as the simple solution, a short-cut route for transforming the construction sector.” This thinking is partly based on claims that growing, transporting, and processing timber products have less impact on the environment, now and in the future. However, the study showed not only that all construction materials industries are making significant efforts towards decarbonisation but also that buildings constructed from timber-based materials are not inherently carbon neutral. To correctly assess their impact, it is essential to consider all life cycle stages, from raw material sourcing to production, transportation and ultimately disposal. The study also highlights that timber-based construction products currently offer limited potential for global climate change mitigation. Additionally, it demonstrates that protected forests (where human activity is absent and the natural environment is preserved in its entirety) and sustainably managed forests have the highest potential to mitigate climate change. Therefore, initiatives focusing on preserving and expanding these areas, supported by reforestation projects, are the actions that currently offer the greatest potential for climate mitigation.

There is also an urgent need for LCA studies covering the entire life cycle of buildings and products. Some LCA studies of building materials are not carried out with the necessary level of detail or intentionally omit certain life cycle stages, leading to incomplete and misleading conclusions. Developing specific guidelines for LCA studies is therefore becoming increasingly urgent in order to address these issues. The study also highlights how architects should choose the most suitable materials for their projects on a case-by-case basis. In recent years, the Italian ceramic industry has made significant progress in improving its efficiency and reducing its energy consumption thanks to constant investments in upgrading and digitalising its production plants.

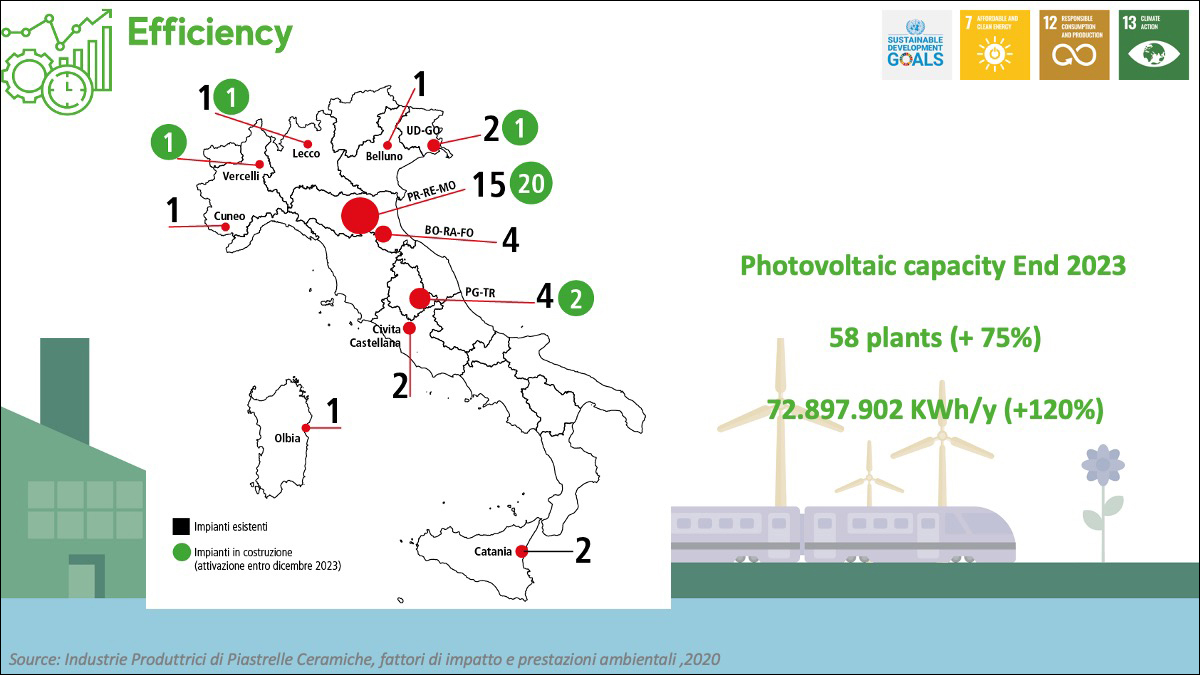

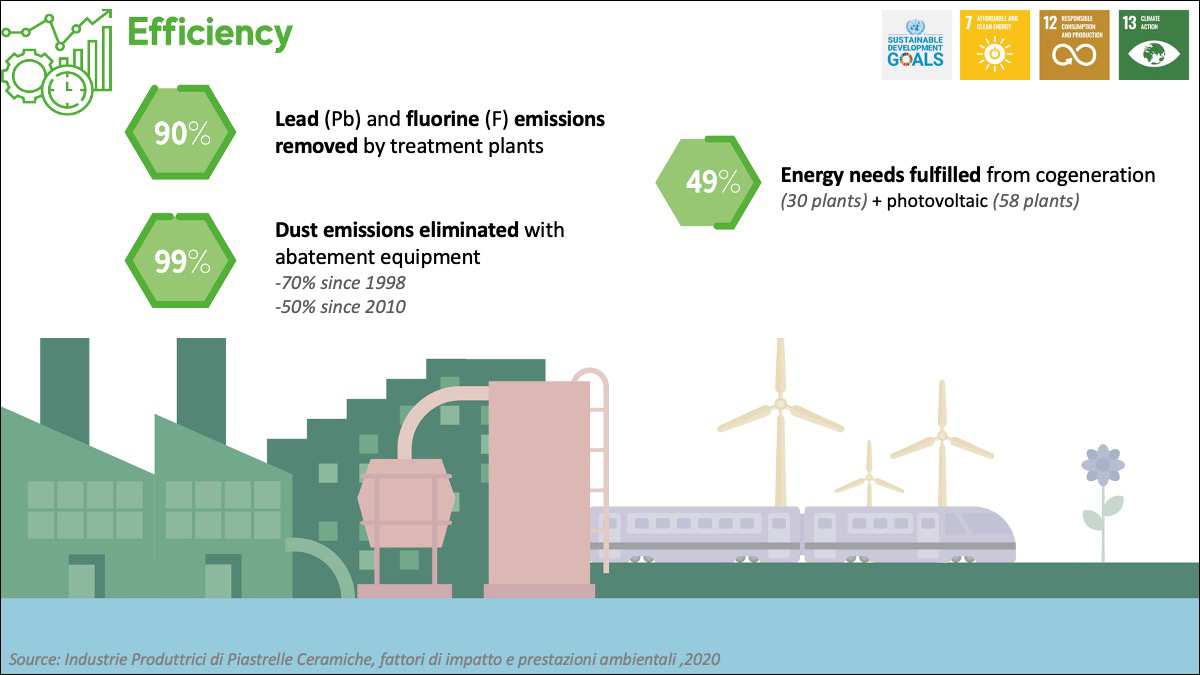

“All of this has been achieved by investing around €2 billion over the last five years, close to 10% of revenues (far higher than the average figure for the Italian manufacturing industry as a whole),” explained Mauro Rullo, climate policy and sustainability officer at Confindustria Ceramica, in his presentation. This has enabled the Italian ceramic industry to improve its environmental performance, particularly in terms of emissions reductions (90% of fluorine and lead emissions and 99% of dust emissions are removed by means of abatement systems). In addition, 49% of the industry’s electricity requirements are met using photovoltaic systems (a total of 58 photovoltaic arrays were installed by the end of 2023, more than double the 2022 figure) and high-efficiency cogeneration systems. At the same time, the industry boasts a very high level of circularity, with 96% of production facilities reusing all solid waste within their production processes. “For many years now, the Italian ceramic industry has been committed to transparency, choosing to disclose its products’ environmental performance across their entire life cycle through a voluntary Environmental Product Declaration (EPD),” added Rullo. “This enables end consumers to make informed purchasing decisions.”

Confindustria Ceramica’s industry-wide EPD, obtained from official data and validated by independent third-party auditors, reports the average environmental performance of Italian ceramic manufacturers. Many Italian ceramic producers also publish their own product-specific EPDs to highlight their commitment to efficiency and decarbonisation. “All of this translates into increasingly sustainable and innovative products that represent the very best of Italian manufacturing excellence,” concluded Rullo.

December 2023

Architects

Architects

Construction firms

Construction firms